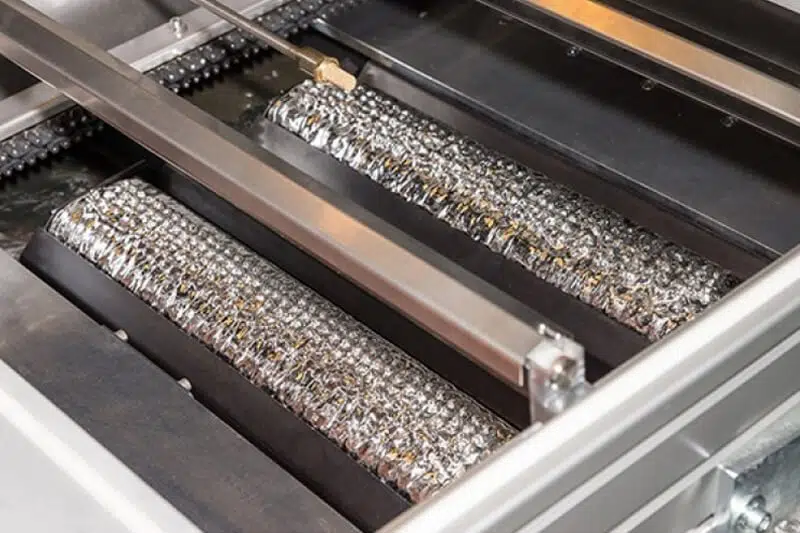

What is Wave Soldering?

Wave soldering is employed within the creation of printed circuit boards. One of the foremost common kinds of bulk soldering is wave soldering.

After years of efforts, JHYPCB has established a complete supply chain control system for components sourcing. To produce the best PCB assembly products for customers, we have established long-term cooperation with the world’s most famous component distributors. They can provide us with the best quality components at the most favorable price, such as Digi-Key Electronics, Mouser Electronics, Avnet, Farnell, Arrow Electronics, Future Electronics, and Newark.

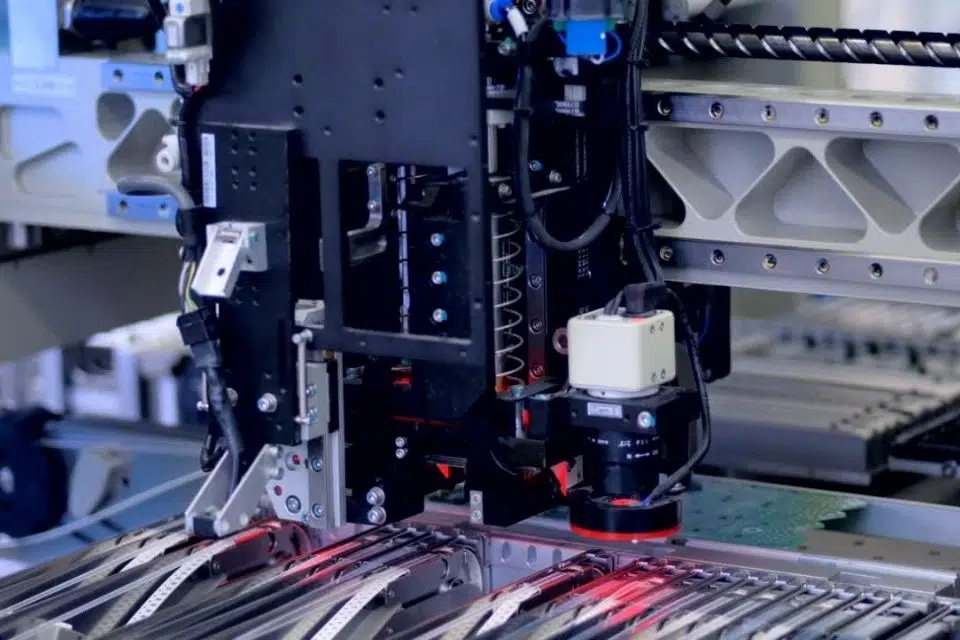

JHYPCB provides high-reliability Rapid PCB Prototyping and Quick Turn PCB manufacturing service at a low-cost price. With state-of-the-art facilities and an experienced professional technical team, we manufacture first-class printed circuit boards for customers around the world.

JHYPCB is a senior PCB assembly manufacturer located in China. Through this page, you will learn about our overall PCB assembly capabilities, such as process capability, assembly type, delivery time, factory scale, component procurement, PCB manufacturing, etc. Start discussing your PCB assembly project now.

JHYPCB is an electronic manufacturing service supplier located in Shenzhen, China, providing one-stop comprehensive solutions for contract manufacturing services, including PCB prototyping, PCB manufacturing, PCB assembly, and component sourcing services. Our core competitive advantages are low cost, fast turn PCB manufacturing, assembly services, and the highest quality standards.

Thank you for choosing us to provide you with PCB manufacturing and assembly services. Please read the following guidelines carefully so that we can provide you with more convenient and better services.

Wave soldering is employed within the creation of printed circuit boards. One of the foremost common kinds of bulk soldering is wave soldering.

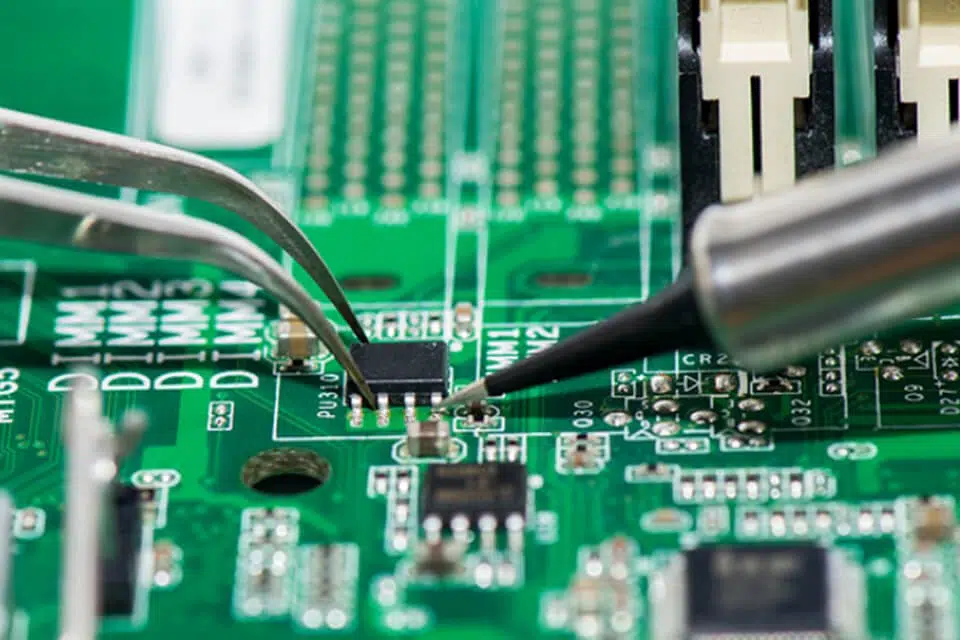

When it involves the PCB assembly process, reflow soldering is the most generally used method of soldering, which is widely used for PCB assembly.

Whether lead-free solder vs. lead solder, the functions are nearly identical. But different products and applications may require other solders.

PCB prototypes are early samples of products built with the only real purpose of testing design ideas to determine if they work.

Explore the top 5 benefits of turnkey PCB assembly: reduced time to market, access to advanced technology and equipment, improved quality and reliability, flexibility and scalability, and cost savings. This blog dives into how turnkey PCB assembly services enable fast prototyping and production while ensuring quality. Learn why outsourcing PCB assembly allows you to focus on core competencies.

When it involves PCB assembly, you have got to be very careful with it. Choosing the proper PCB manufacturer can make the method much easier.

Small batch PCB assembly is your bespoke solution for well-defined flexibility for mounting components on a relatively small batch of bare boards!

An SMD, or surface-mounted device, is an electronic component that you just would find on a board. An SMT is a way of placing electronic parts (like an SMD) on the board. In electronic manufacturing services, the SMT procedure frequently works with SMDs, probably adding to the uncertainty.

How to Reduce Your PCB Assembly Cost? When it involves reducing the price of a PCB Assembly project, there are some steps you’ll be able to take that not every company considers.

Through Hole technology is a technique for building electronic circuits within which the pin-through-hole (PTH) components are embedded through gaps penetrated into computer circuit boards (PCBs).

Accurate and intuitive PCB assembly drawings will help your PCB assembly project complete more smoothly.

Fill in the form below and our team will be happy to assist you